Design for

Manufacturing Services

We help your mental sketches

take solid form.

Optimize your product for efficient manufacturing and streamlined assembly—

reducing costs and accelerating production.

Better Designs Lead to Better Products

DFM ensures that your designs are optimized for efficient, cost-effective production and assembly. At Aprios, we focus on creating parts and assemblies that streamline the manufacturing process, reduce waste, and enhance quality. By carefully selecting materials and designing parts that align with the capabilities of both injection molding and 3D printing, we help you minimize production costs and lead times, delivering high-quality results that meet your needs and exceed your expectations.

Poor Design Decisions Can Lead To Costly Mistakes

Designing with efficiency in mind is essential to avoiding delays, controlling costs, and ensuring compliance. Early planning and expert guidance can help you identify potential pitfalls, streamline production, and set your project up for success.

MANUFACTURING DELAYS from avoidable design flaws.

INCREASED PRODUCTION COSTS due to material choices and manufacturing methods.

ASSEMBLY ERRORS AND LONGER BUILD TIMES from overly complex designs.

EXCESSIVE PARTS IN YOUR DEVICE leads to higher tooling, labor, and assembly costs.

REGULATORY COMPLIANCE RISKS if tolerances and validation aren't addressed early.

What DFM Can Do for You

By incorporating DFM principles, we help you create designs that are easier and cheaper to manufacture, improving the quality and performance of your products. Let us work together to optimize your designs for manufacturability, ensuring your business benefits from reduced costs, enhanced durability, and quicker production times.

Simplifying Part Design and Ensuring Consistency

Simplifying part design reduces mold complexity and costs, while maintaining uniform wall thickness helps prevent issues like warping and incomplete filling. By opting for straightforward designs over intricate ones, production becomes more efficient. Our DFM design approach provides cost-effective solutions.

-

Managing Complex Shapes

- Simplifying the geometry of your parts reduces the complexity of the mold, making manufacturing easier and more cost-effective. For instance, opting for straightforward geometries over intricate undercuts allows for simpler, cheaper mold designs.

-

Uniform Wall Thickness

- Maintaining consistent wall thickness helps avoid issues like warping, sinking, or incomplete filling. For example, ensuring uniform walls in electronic device housings promotes proper cooling and prevents uneven shrinkage.

Avoiding and Resolving Failure Points

Designs are refined to avoid potential failure points by using fillets instead of sharp corners, which distributes stress evenly. This practice enhances durability in both injection molding and additive manufacturing applications.

-

Avoiding Sharp Corners

- Sharp corners can create stress concentrations and potential failure points. Instead, use fillets (rounded corners) to distribute stress more evenly and improve the flow of molten plastic.

-

Eliminating Tooling Pitfalls

- Designing parts to avoid undercuts (a feature of a molded part that prevents the part from being ejected from the mold without additional mechanisms or actions) that require side actions or lifters in the mold can significantly reduce costs and complexity. For instance, designing snap-fit features without additional mold movements streamlines production.

Enhancing Part Strength and Ease of Assembly

Rather than increasing wall thickness, strategically placed ribs add strength and rigidity. Bosses are integrated for fastening, ensuring stability and durability across both injection molding and additive manufacturing processes.

-

Using Ribs to Increase Part Strength

- Instead of increasing wall thickness, add strength and rigidity with strategically placed ribs. For example, a thin-walled plastic cover can achieve enhanced structural integrity through well-placed ribs.

-

Bosses for Assembly

- Integrate bosses (cylindrical protrusions) for screws or fasteners in areas needing assembly, ensuring they are supported by adjacent walls or ribs to distribute stress and maintain durability.

Optimized Material Selection and Usage

Choosing the appropriate materials is crucial. Our material recommendations are selected to meet performance requirements, such as high-flow thermoplastics for injection molding or specialized resins for additive manufacturing. This approach ensures proper filling, reduces cycle and print times, and enhances efficiency.

-

Avoiding Sharp Corners

- Selecting materials that are compatible with injection molding and meet the performance requirements of your parts is crucial. Using a high-flow thermoplastic for thin-walled parts ensures proper filling and reduces cycle times, enhancing efficiency.

Learn About DFM

with Ray Schenk

Watch our Senior Engineer, Ray Schenk, discuss the value of Design for Manufacturing (DFM) in this insightful video. Ray explains how DFM principles enhance manufacturability, reduce costs, and improve product quality, providing our customers with efficient and effective production solutions. Discover how integrating DFM into your design process can transform your manufacturing outcomes.

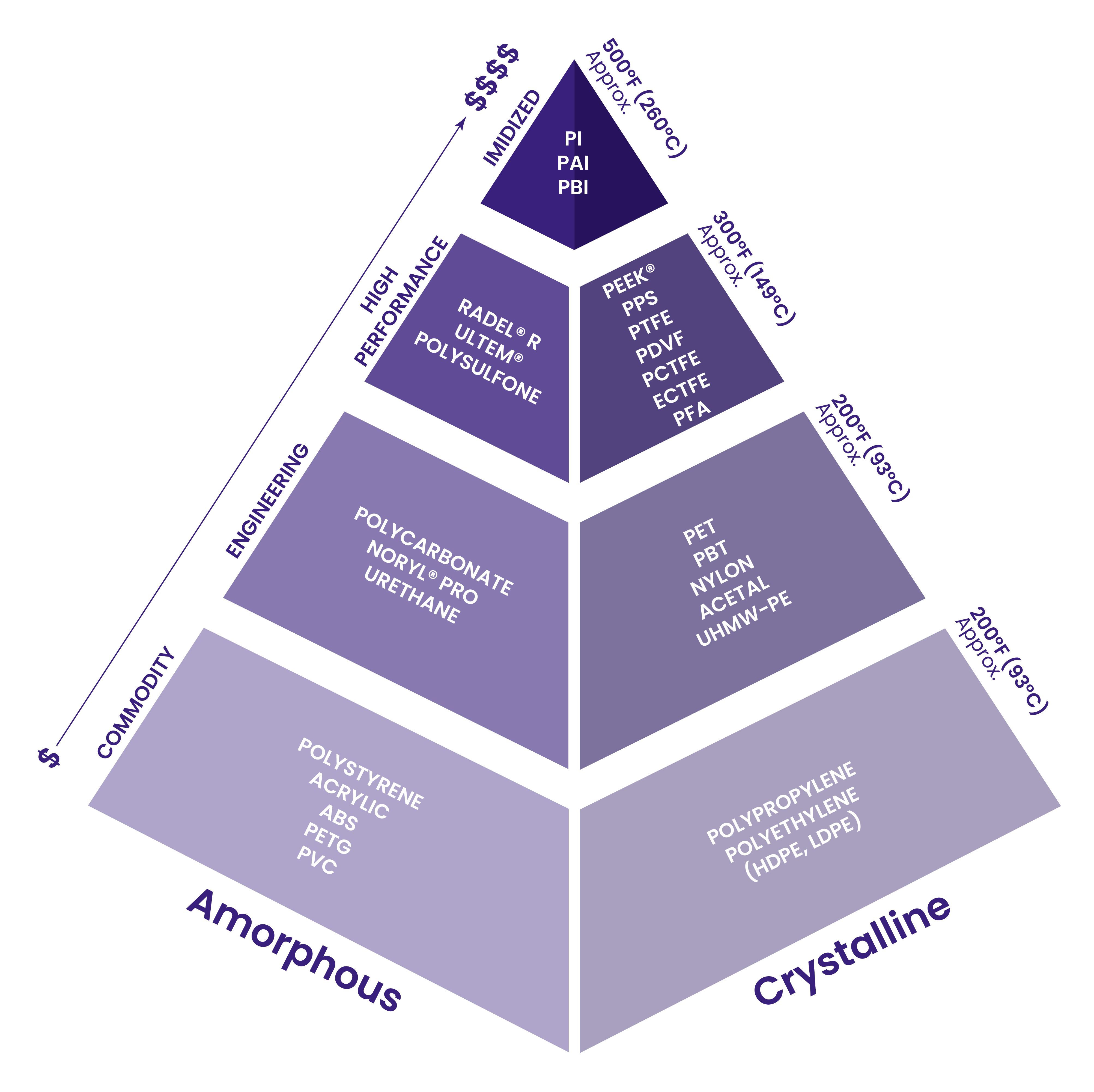

Find the Right Material for Your Application

Material selection plays a critical role in manufacturability, performance, and cost. Whether you need high-temperature resistance, flexibility, chemical compatibility, or medical-grade biocompatibility, Aprios offers a comprehensive selection of thermoplastics, elastomers, and high-performance materials for injection molding and additive manufacturing.

Our thermoplastic material selection guide will help you:

- Browse materials by category, properties, and applications.

- Compare options for strength, rigidity, thermal resistance, and more.

- Understand which materials are best suited for your project’s requirements

Why Trust Us?

At Aprios, we know that great product design is about more than just function, and includes important details about manufacturability and efficiency. That’s why we take a collaborative, holistic approach, considering DFM, DFAM, and DFA, helping engineers reduce risk, cut costs, and speed up production without sacrificing quality.

“In addition to improving the manufacturability of the parts, Aprios made modifications to reduce scrap.”

“Some of the components are so intricate that we can’t take the work to anywhere else. I am confident in Aprios’ ability to work with us for continuous improvement and to meet growing production demand. ”

3 Steps To Smarter Manufacturing & Assembly

Experience smooth design optimization and seamless integration into your manufacturing process.

Submit Your Design

Upload CAD files for evaluation.

DFM Review

We assess manufacturability, assembly efficiency, and design optimizations.

Refine & Optimize

Collaborate with our experts to implement improvements.

Understanding the Boundaries of DFM

DFM is a powerful tool for enhancing manufacturability and efficiency, but it works best when integrated with comprehensive design, engineering, and quality control practices.

-

DFM Isn't a Substitute for Detailed Engineering and Product Development

While DFM optimizes designs for manufacturability, it doesn't replace the need for detailed engineering and thorough design work. It enhances the process but can't compensate for a lack of technical precision or thorough design validation.

-

DFM Isn't a One-Size-Fits-All Solution

DFM principles vary depending on the manufacturing method, materials, and product requirements. What works for injection molding may not apply to additive manufacturing, and vice versa. DFM must be tailored to each specific project to be effective.

-

DFM Isn't a Guarantee of Perfect Products

Even with optimized designs, unforeseen issues can arise during production. DFM minimizes risks and enhances manufacturability, but it doesn't eliminate the need for rigorous quality control and testing throughout the production process.

-

DFM Isn't a Replacement for Prototyping

While DFM can reduce the need for multiple design iterations, it doesn't eliminate the need for prototyping. Prototyping is still essential to test and validate the physical aspects of a design before full-scale production.

-

DFM Isn't a Quick Fix

Implementing DFM principles requires time and collaboration between design and manufacturing teams. It’s an investment in the design phase that pays off in production efficiency and cost savings, but it isn't an immediate solution for existing manufacturing issues.

-

DFM Isn't an All-Inclusive Cost Reduction Strategy

While DFM can lead to cost savings by optimizing the design for efficient production, it doesn't account for all potential cost factors. Material costs, labor, and overhead still play significant roles in the overall production cost.

-

DFM Isn't Solely About Simplification

DFM focuses on optimizing designs for manufacturing, which sometimes involves simplification, but it also includes strategic enhancements. The goal is to make the design manufacturable without compromising functionality or performance.

Make your designs production-ready with Aprios.