INJECTION MOLDING SERVICES

Experienced Capability.

Exceptional Craftsmanship.

Mastery in every mold.

Precision Plastics for Mission Critical Parts

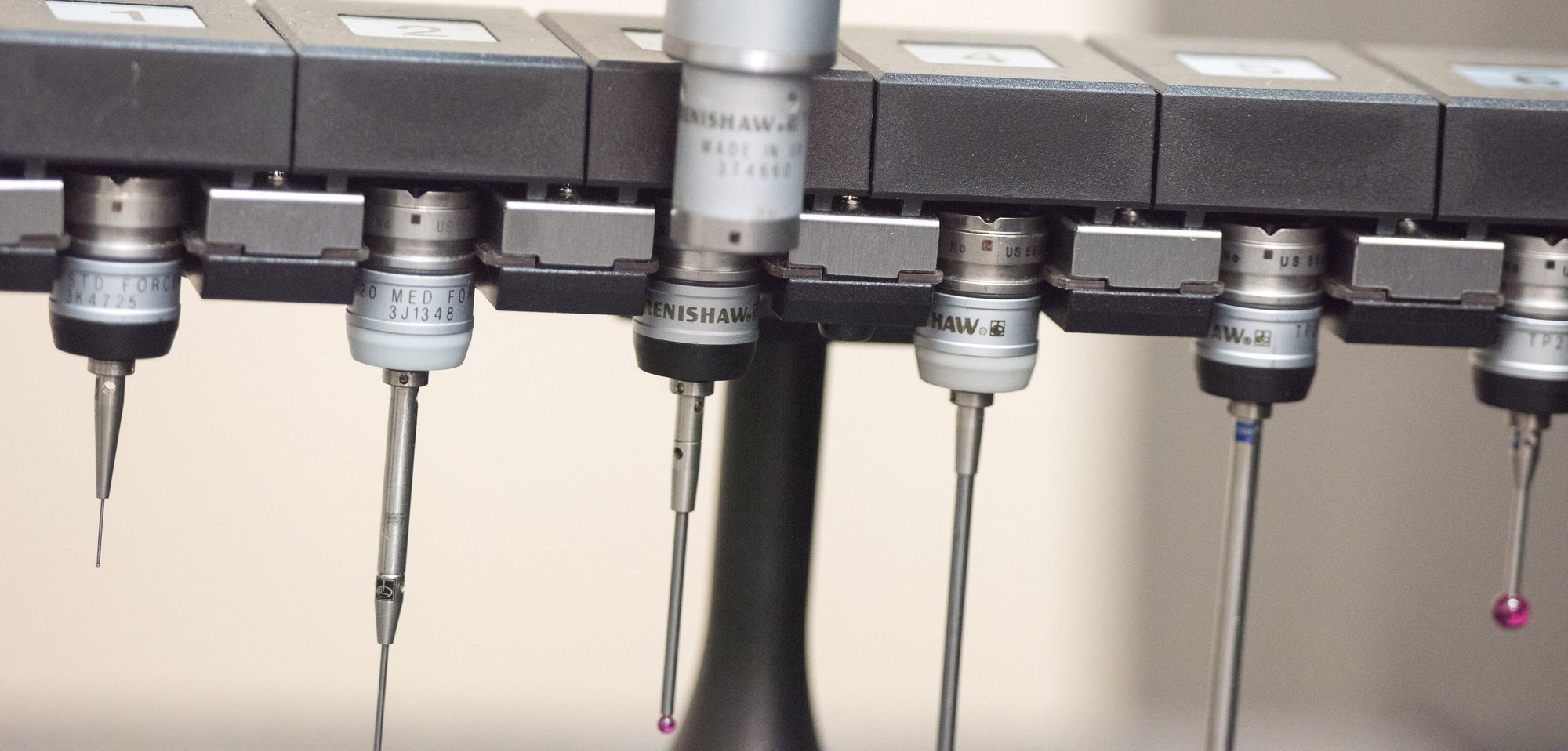

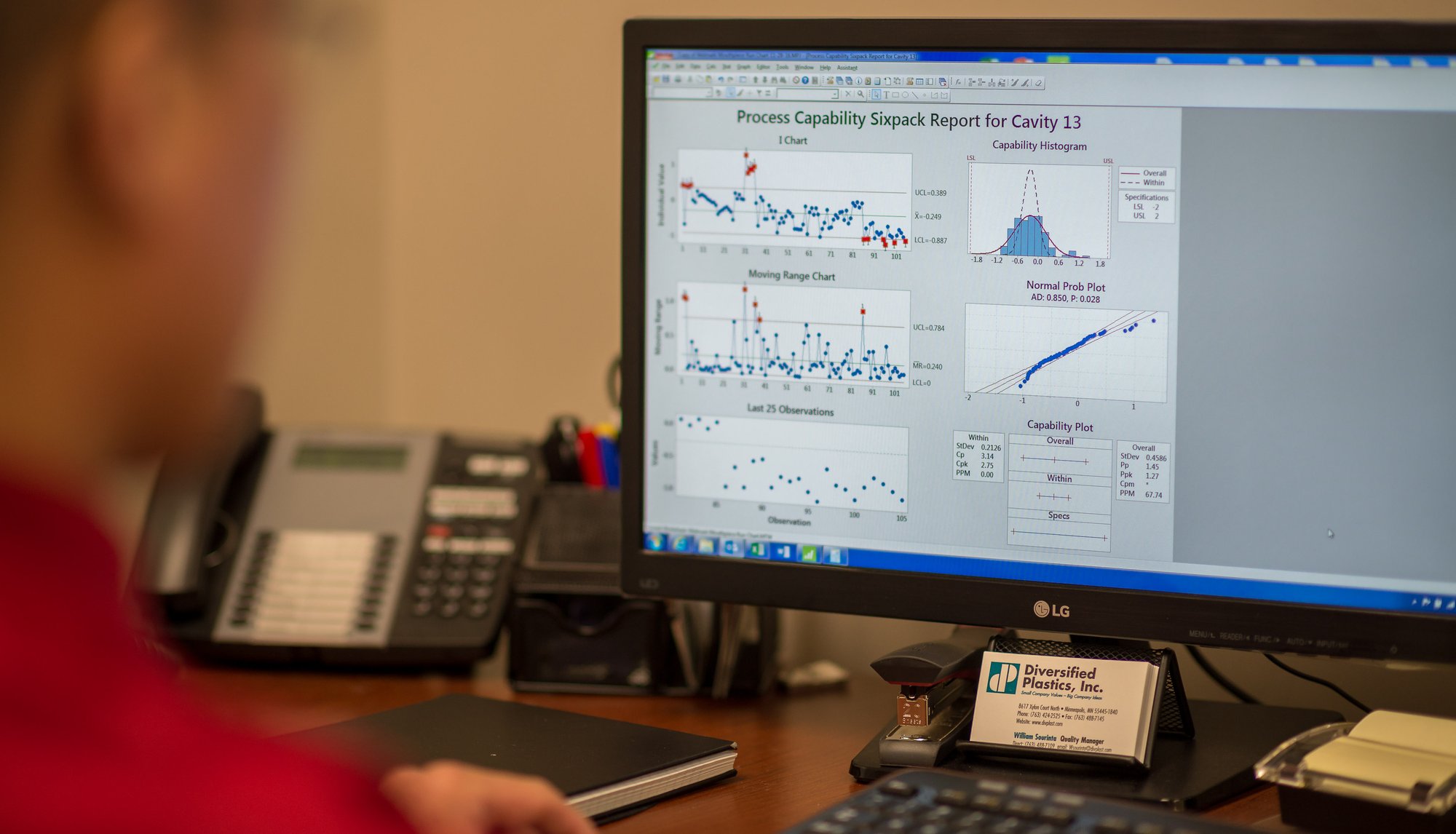

High-performance injection molding demands a scientific approach. We use Scientific Injection Molding (SIM) to ensure every part meets the strictest standards for precision, repeatability, and compliance. Whether you’re manufacturing medical devices, aerospace components, or critical industrial parts, our data-driven process eliminates variation and maximizes quality.

Is Your Injection Molding Partner Costing You?

Identify and address key inefficiencies that impact your cost, quality, and timelines.

INCONSISTENT PART QUALITY leads to failed assembles.

LONG LEAD TIMES slow down product development.

REGULATORY NON-COMPLIANCE creates audit risks.

DESIGN CONSTRAINTS limit innovation.

MANUFACTURING INEFFICIENCIES drive up costs.

Overmolding joins two materials into one finished part. It’s how we add grip, comfort, or durability without extra assembly. The process works well for ergonomic designs or parts that take repeated use. We focus on clean bonds and consistent results from run to run.

Insert molding integrates metal or plastic inserts into the molded parts during the injection process. This technique enhances the strength and functionality of components, making it perfect for complex assemblies. Our expertise in insert molding allows us to produce parts with embedded reinforcements, electrical components, or threaded inserts with precision.

We offer specialized medical molding services to produce high-precision, sterile components for the healthcare industry. Our Class 8 Clean Room ensures that all medical parts are manufactured in a controlled, contamination-free environment. This guarantees the highest standards of cleanliness and compliance with medical regulations.

Micro injection molding is a technique for producing tiny and precise components using minimal resin volumes in the injection procedure. We use micro injection molding to make small, detailed parts with tight precision — the kind needed in medical, electronic, and automotive work where every fraction of a millimeter counts.

Injection Molding Ancillary Services

Prototypes to Production at Scale

Our injection molding services cater to small quantity prototypes, as well as full-scale production. Whether you need a few test pieces or millions of units, we have the capability to meet your demands efficiently.

Tool Transfer

We have a defined project management and quality assurance process for intaking tools from other manufacturers. Our team can repair and modify existing tools to get your production back on track quickly.

Post-Processing and Assembly

Our secondary operations include machining, bonding, and finishing. We can also offer assembly and packaging in our Class 8 Clean Room, maintaining the highest standards of cleanliness and quality.

Scientific Injection Molding For Uncompromising Quality

Achieve flawless precision and reliability with advanced molding techniques for high-performance applications.

-

Tight Tolerance CapabilitiesFor complex geometrics and micro molding.

-

ISO 13485 & FDA-Compliant ProcessesFor MedTech and critical applications.

-

Decoupled Molding TechniquesFor maximum precision and repeatability.

-

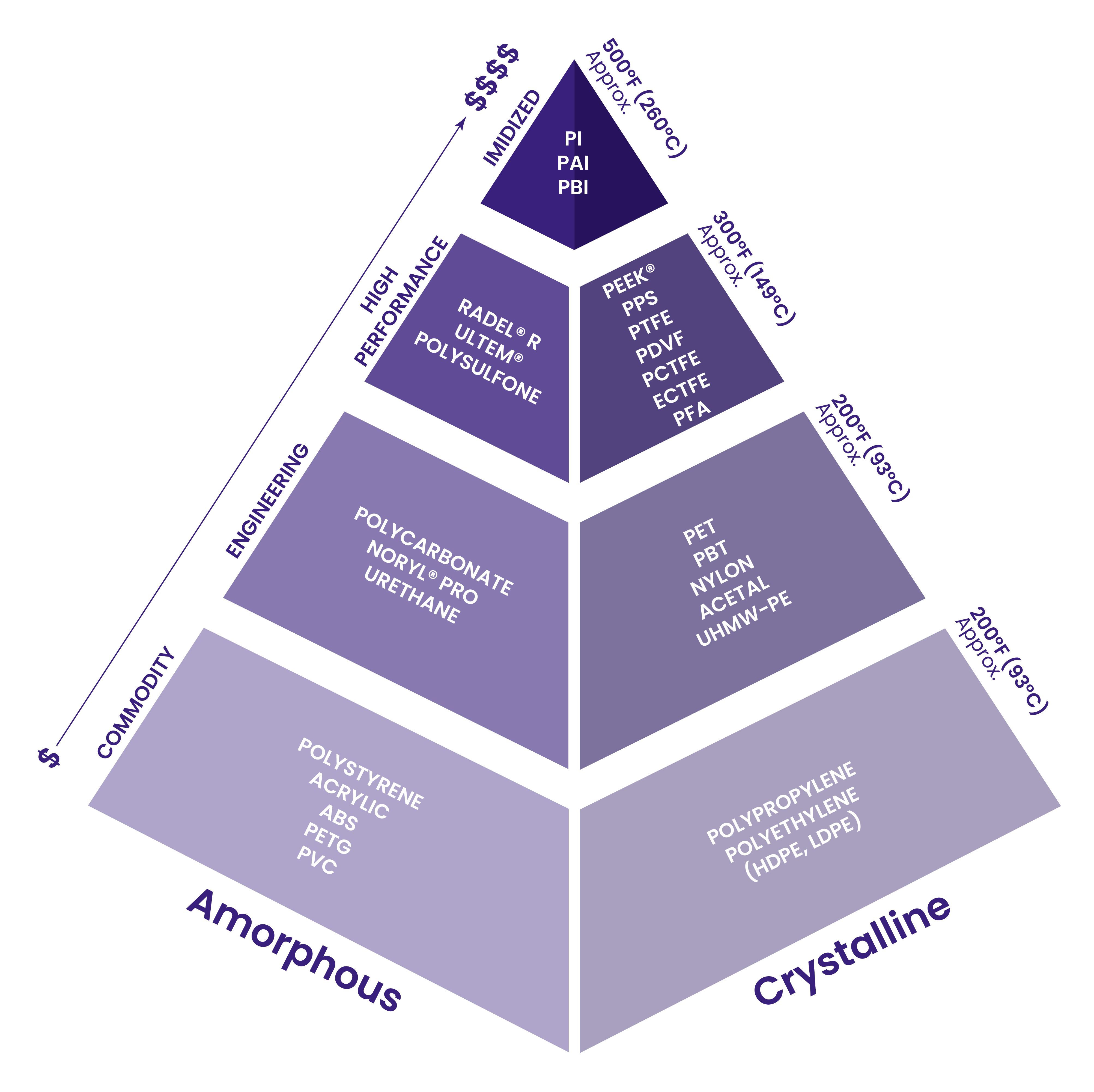

Material ExpertiseIn high-performance and medical-grade polymers.

-

End-To-End SupportFrom DFM consultation to full-scale production.

.png?width=619&height=735&name=Placeholder%20Image%20(19).png)

From Concept to Production

From first concept to full-scale production, every molded part follows a path. We guide you through each stage—Design for Manufacturability (DFM), Prototype Tooling, Bridge Tooling, and Production Tooling—so your part is optimized for performance, cost, and scalability at every step.

Injection Molding Lifecycle Timeline

-

Design for Manufacturability (DFM)

This is where it all begins. We collaborate with you to refine your part design, reduce risk, and ensure it’s moldable, manufacturable, and cost-effective. Good DFM service sets the foundation for success.

-

Prototype Tooling

A low-investment mold that helps you test your part in real-world materials and get early feedback. It’s essential for validating design intent and function before locking in production details.

-

Bridge Tooling

Perfect for short-run production or when demand is ramping up. This stage fills the gap between prototyping and full-scale tooling—giving you molded parts faster while final production tooling is underway.

-

Production Tooling

Your long-term tool built for repeatability, efficiency, and high-volume output. This is where consistency, cycle time, and quality control really matter—and where all the upfront planning pays off.

By incorporating these considerations into your design, we ensure a more efficient injection molding process, leading to high-quality, cost-effective parts.

Why Trust Aprios with your Injection Molding Needs

Quality Assurance and Compliance

We adhere to stringent quality assurance protocols and comply with industry standards to ensure the reliability of every part we produce. Our comprehensive testing and inspection processes guarantee that each component meets your exact specifications. For more information, please visit our Quality page. This commitment to quality reduces the risk of defects and enhances the overall performance of your products.

Design for Manufacturing (DFM)

Our Design for Manufacturing (DFM) services help you optimize your designs for efficient and cost-effective production. By collaborating early in the design process, we identify potential issues and suggest improvements to enhance manufacturability. This proactive approach reduces time-to-market, lowers production costs, and ensures that your products are designed with manufacturing efficiency in mind.

Quick-Turn Tooling

We understand the importance of speed in bringing new products to market. Our quick-turn tooling services enable us to deliver parts within a month after placing an order. This rapid turnaround time allows you to accelerate your product development cycles and respond swiftly to market demands, giving you a competitive edge.

Partnership and Support

We view our clients as partners and are dedicated to supporting your success from concept to completion. Our experienced team is available to assist with design, prototyping, production, and post-production services. This end-to-end support ensures a smooth and successful project execution, allowing you to focus on your core business objectives.

We're Here to Help You Succeed

Your challenges are our priority as we find tailored solutions

3 Steps For Precision Manufacturing

Enjoy a seamless integration into your production process

Share Your Files

We’ll sign an MNDA and assess manufacturability for free.

Recieve A Quote

Clear pricing and lead times, no surprises.

Place Your Order

Lock in production and move forward with confidence.

FAQs

-

What is injection molding?

Injection molding is a manufacturing plastic parts method where molten resin is injected into a mold cavity and cooled into shape. It’s ideal for producing precise, repeatable plastic products across industries that require tight tolerances and dependable consistency.

-

How custom plastic injection molding works?

The injection molding process starts when an injection unit pushes heated material through a reciprocating screw into the mold halves. Once the cooling time finishes, the tool opens and the part is released, ready for inspection, assembly, or downstream finishing.

-

What industries use injection molding?

Injection molding supports industrial processes across medical, aerospace, automotive, and consumer markets, where precise plastic parts are required at scale.

-

Do you offer plastic injection molding services for both prototypes and production runs?

Yes. At Aprios, we handle both prototype and production runs, using the same attention to detail in tooling services, materials, and process control to keep every batch consistent and reliable.

-

What is the typical lead time for injection molding services?

Lead time depends on part complexity and tooling readiness, but most projects move from quote to shipment within a few weeks. Factors like cooling time, validation, and other components can adjust schedules slightly.

-

Do you offer ISO 13485 injection molding for medical devices?

Yes. We are ISO 13485 certified and FDA registered, providing cleanroom molding with full quality systems to support medical-grade components.

-

What makes Aprios a reliable plastic injection molding manufacturer?

We combine decades of experience with precise equipment and a disciplined process. Our injection molding machine controls pressure, temperature, and chemical reaction variables carefully to ensure parts stay within spec for both thin walls and thick walls.

-

How much does injection molding cost?

Costs vary based on material, tooling, and production volume, but we focus on efficient setup and repeatability, delivering long-term savings through optimized tooling and steady cycle times.

Need Top-Quality Injection Molding?

DFM in Plastic Injection Molding: Practical Design Tips for Better Parts

A quick-start guide for engineers designing smarter, more manufacturable plastic parts.

WHAT'S INSIDE:

- Draft angles, wall thickness, and parting line best practices

- How to avoid common pitfalls like sink, warping, and knit lines

- Tooling design insights: gating, venting, and mold flow

- Rib, boss, and corner radius guidelines

- How mold flow analysis helps you get it right the first time