EPU 41: High-Performance Elastomeric Polyurethane Resin

Elastomeric Polyurethane (EPU 41) is a versatile, production-grade additive manufacturing resin developed by Carbon. It is engineered to deliver...

Elastomeric Polyurethane 44 (EPU 44) is a highly elastic and tear-resistant material developed by Carbon for its Digital Light Synthesis™ (DLS) technology. This advanced elastomer is engineered for durability, offering excellent performance in demanding applications that require flexibility, resilience, and fatigue resistance. Its unique properties make it a compelling choice for engineers and designers looking to create complex, robust elastomeric parts through additive manufacturing.

EPU 44 is distinguished by its exceptional elasticity, allowing it to stretch significantly and return to its original shape without permanent deformation. This high resilience is critical for parts that undergo repeated cycles of compression, stretching, or bending, providing a reliable and long-lasting performance.

One of the key attributes of EPU 44 is its remarkable tear strength. This characteristic provides added durability, reducing the risk of tears or punctures, which is particularly important in components subjected to dynamic stress or harsh environmental conditions.

Parts made with EPU 44 demonstrate impressive resistance to fatigue, meaning they can withstand repeated loading and unloading cycles over extended periods without degrading or failing. This makes it an ideal material for functional prototypes and end-use parts that experience continuous movement or stress.

EPU 44 meets ISO 10993-5 and ISO 10993-10 biocompatibility standards, making it suitable for certain medical device applications where skin contact is a consideration. This compliance opens up possibilities for components within the medical industry, from wearable devices to specialized equipment, where direct contact with patients is required.

The material exhibits good resistance to a variety of chemicals, including many common oils, greases, and solvents. This chemical inertness contributes to its durability and suitability for industrial components that may come into contact with such substances.

Want Advanced Durability Without Compromising Flexibility?

EPU 44 delivers exceptional elasticity and energy return—ideal for demanding applications.

EPU 44's unique combination of elasticity, tear strength, and fatigue resistance makes it highly suitable for a diverse range of challenging applications, particularly in industries requiring high-performance elastomers.

Due to its excellent compression set and tear strength, EPU 44 is an ideal material for producing custom gaskets and seals. These components can be designed with intricate geometries not possible with traditional manufacturing methods, providing superior sealing capabilities in demanding environments.

The material's biocompatibility and flexibility make it well-suited for components in wearable technology, such as straps, cushioning, and protective enclosures. Its comfort and durability are beneficial for devices that are in prolonged contact with the skin.

EPU 44 is utilized for shoe cushioning, providing responsive and durable comfort in footwear. Its elastomeric properties contribute to impact absorption and energy return, making it a valuable material for high-performance athletic and everyday shoes.

EPU 44 is frequently used for rapid prototyping of elastomeric parts, allowing designers and engineers to quickly test and iterat e designs with a material that closely mimics the properties of final production materials. This accelerates the product development cycle significantly.

EPU 44’s ability to absorb energy and rebound makes it a viable choice for damping and cushioning components. This can include shock absorbers, vibration isolators, and ergonomic grips, where impact absorption and comfort are paramount.

Beyond specialized applications, EPU 44 is utilized for a variety of general industrial components requiring a durable, flexible, and resilient material. This can range from grippers in automation to custom fixtures and soft tooling elements.

Read More About Ensure Quality with Tailored Quality Control Plans

EPU 44, as an elastomeric polyurethane, offers a distinct set of properties when compared to traditional thermoplastic elastomers (TPEs) and other rubber-like materials often used in injection molding. While many injection molding processes can produce flexible parts, EPU 44, through Carbon's DLS technology, excels in creating complex geometries with isotropic properties that are challenging or impossible to achieve with conventional methods.

When considering materials like Thermoplastic Polyurethane (TPU), EPU 44 often provides superior tear strength and fatigue resistance, particularly beneficial for components that undergo repeated stress cycles. While TPUs are known for their abrasion resistance and elasticity, EPU 44 can offer a higher degree of elastic recovery and a broader operating temperature range, making it more robust in extreme conditions. Compared to traditional rubber materials like silicone or natural rubber, EPU 44 can offer greater design freedom, allowing for intricate internal lattices and variable densities within a single part, which can lead to optimized performance characteristics such as tunable stiffness or enhanced cushioning. This level of design complexity is not typically achievable through standard injection molding for these materials. For companies focused on medical injection molding, the ability to create highly customized, high-performance elastomeric components with properties that surpass those of conventionally molded TPEs can be a significant advantage.

Struggling to Balance Sustainability and Strength?

Explore how EPU 44 meets both environmental and functional demands in one material.

While EPU 44 offers significant advantages, it also has certain considerations that should be taken into account during material selection and design.

Like many additive manufacturing materials, EPU 44 requires post-processing steps, including washing and a thermal cure, to achieve its final mechanical properties. This adds to the overall manufacturing time and can impact the cost compared to some traditional manufacturing methods.

As a specialized resin for advanced additive manufacturing, EPU 44 may have a higher material cost compared to commodity thermoplastics used in high-volume injection molding. This can influence its suitability for extremely cost-sensitive, large-scale production runs.

While EPU 44 possesses good general durability, prolonged exposure to UV radiation can potentially lead to changes in color or mechanical properties over time, particularly in outdoor applications. For parts intended for continuous outdoor use, protective coatings or design considerations for UV exposure may be necessary.

Currently, EPU 44 is primarily available in black. For applications requiring specific colors for branding or functional differentiation, post-processing with dyes or paints would be necessary, adding an extra step to the manufacturing process.

Read More About Why Invest in Carbon DLS Additive Manufacturing | Aprios

EPU 44 stands out as a highly versatile and resilient elastomeric material, offering exceptional performance in demanding applications that require flexibility, durability, and resistance to fatigue. Its unique combination of high elasticity, superior tear strength, and impressive fatigue resistance makes it an ideal choice for engineers and designers pushing the boundaries of product design. When considering medical injection molding, its biocompatibility and the ability to create complex geometries with predictable performance are particularly valuable. EPU 44 empowers the creation of highly functional, custom elastomeric components that can withstand rigorous use and perform consistently across a wide range of environments.

Ready to integrate EPU 44 into your design? Get in touch for expert advice and solutions tailored to your project!

You can also view our Material Selection tool.

Elastomeric Polyurethane (EPU 41) is a versatile, production-grade additive manufacturing resin developed by Carbon. It is engineered to deliver...

Elastomeric Polyurethane (EPU 40) is a high-performance additive manufacturing material developed by Carbon, renowned for its unique combination of...

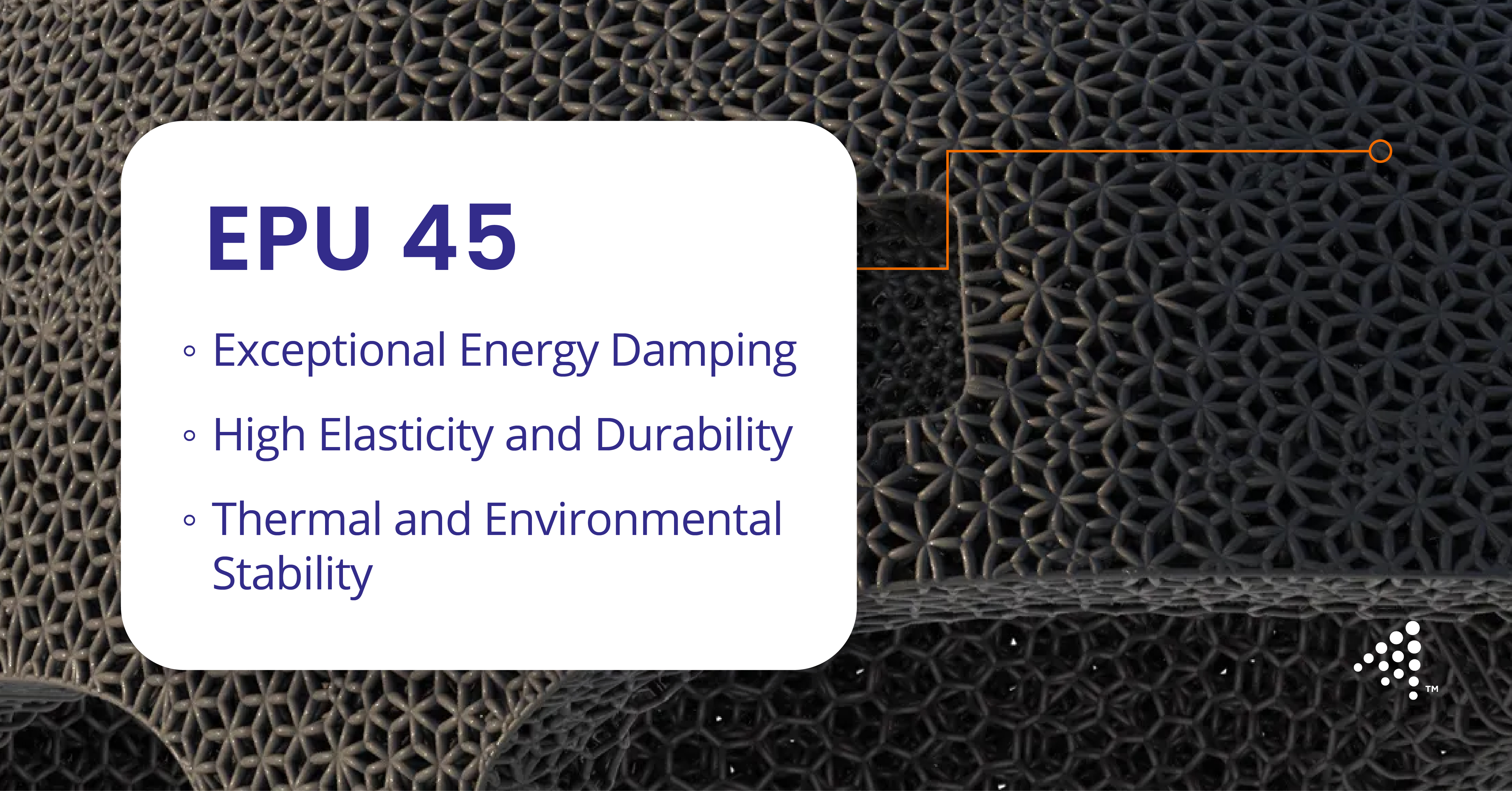

Elastomeric Polyurethane (EPU) 45 is a high-performance photopolymer resin engineered for the Carbon Digital Light Synthesis™ (DLS™) process. This...