Material Optimization: Choose the Right Materials for the Job

The choice of material is a foundational decision that influences every subsequent stage of a project. It is a critical intersection of design,...

3 min read

Nick Erickson : Oct 24, 2025 9:15:00 AM

The remarkable rise of additive manufacturing is intrinsically linked to the expanding palette of materials available to engineers. The ability to create a complex part directly from a digital file is powerful, but the true potential is unlocked when a specific design is paired with a material whose properties are perfectly suited for the task. The choice of material is as crucial as the design itself, dictating the final part's strength, flexibility, temperature resistance, and biocompatibility.

Navigating the vast landscape of available polymers can be a challenge. Understanding the key differences between the materials used in various additive processes is fundamental to making an informed engineering decision. This overview will explore the material families associated with three prominent technologies: Carbon Digital Light Synthesis (DLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA).

Carbon Digital Light Synthesis (DLS) is renowned for its ability to produce parts with mechanical properties and surface finishes that are comparable to injection-molded plastics. This makes its material families suitable for both functional prototyping and end-use production. The resins are thermosets, meaning they form strong, irreversible covalent bonds during the curing process, leading to excellent durability and performance. Carbon DLS Prototyping is a critical step in transitioning from 3D Printed Prototypes to production-ready components with Plastic Part Design Optimization in mind.

These materials are the workhorses for applications demanding strength, stiffness, and durability. Rigid Polyurethane 70 (RPU 70) is a versatile and tough material, often used for durable housings, enclosures, and consumer product components that need to withstand impact. For even more demanding structural applications, RPU 130 offers superior toughness and impact strength. When high temperature resistance and stiffness are the primary requirements, Epoxy 82 (EPX 82) is an ideal choice, making it well-suited for automotive and industrial components like electrical connectors and brackets.

Carbon DLS excels at producing truly elastomeric parts. Elastomeric Polyurethane 41 (EPU 41) is a high-performance elastomer that exhibits excellent elastic behavior and high energy return, making it perfect for gaskets, seals, and cushioning components. For applications that require flexibility but not true elasticity, Flexible Polyurethane 50 (FPU 50) offers superb durability and fatigue resistance, making it a great option for living hinges, cable enclosures, and other parts that need to bend repeatedly. These materials also support rapid prototyping services and early Design for Additive Manufacturing (DfAM) initiatives.

For the most demanding environments, Carbon offers highly specialized resins. Cyanate Ester 221 (CE 221) provides exceptionally high temperature resistance and stiffness, a vital property for components in the aerospace and automotive sectors. For medical applications, Medical Polyurethane 100 (MPU 100) is a biocompatible and sterilizable material, enabling the production of everything from surgical instruments to patient-specific device components.

Fused Deposition Modeling (FDM) is one of the most widely accessible additive manufacturing technologies, building parts by extruding a thermoplastic filament layer by layer. The materials used are the same thermoplastics found in many conventional manufacturing processes.

Polylactic Acid (PLA) is arguably the most popular FDM material due to its ease of printing and low cost. It prints at relatively low temperatures and exhibits minimal warping, making it excellent for producing early-stage design concepts and form-and-fit prototypes. For a step up in durability, Polyethylene Terephthalate Glycol (PETG) offers better impact and chemical resistance, and is often used for mechanical parts or containers.

For more functional applications, engineers often turn to more robust materials. Acrylonitrile Butadiene Styrene (ABS) is a common engineering plastic known for its heat resistance and durability, used in everything from automotive trim to electronics housings. Nylon offers great strength, flexibility, and low-friction properties, making it suitable for gears and living hinges. For high-impact applications, Polycarbonate (PC) is a top choice, delivering exceptional toughness and heat resistance, though it can be more challenging to print successfully.

Stereolithography (SLA) is known for its ability to produce parts with extremely high resolution and a very smooth surface finish. Like Carbon DLS, it uses photopolymer resins that are cured by a UV light source.

Standard Resins are formulated to produce parts with fine details and a smooth finish quickly, making them perfect for visual models and aesthetic prototypes where mechanical properties are not the primary concern. To create more functional parts, material manufacturers offer a range of Engineering Resins. These include "Tough" or "Durable" resins formulated to simulate the impact resistance of ABS, or "Rigid" resins that mimic the stiffness of glass-filled thermoplastics.

SLA offers a broad array of specialty resins for specific industries. Castable Resins are designed to burn out cleanly with no ash, a critical property for creating investment casting patterns in the jewelry and dental industries. High-Temperature Resins have an elevated heat deflection temperature, allowing them to be used for applications like injection molding tooling or fixtures in secondary manufacturing processes. For medical and dental uses, various biocompatible resins are available to produce highly accurate surgical guides, dental models, and other patient-specific devices.

Additive manufacturing offers a wide range of materials suitable for various applications, from prototyping to end-use parts. Carbon DLS, FDM, and SLA technologies each support unique resins that provide specific benefits and properties. Understanding the available materials and their applications is crucial for selecting the right one for your project.

For expert guidance in choosing the best materials for your additive manufacturing needs, contact Aprios. Our team can help you navigate the options and ensure you get the best results for your designs.

The choice of material is a foundational decision that influences every subsequent stage of a project. It is a critical intersection of design,...

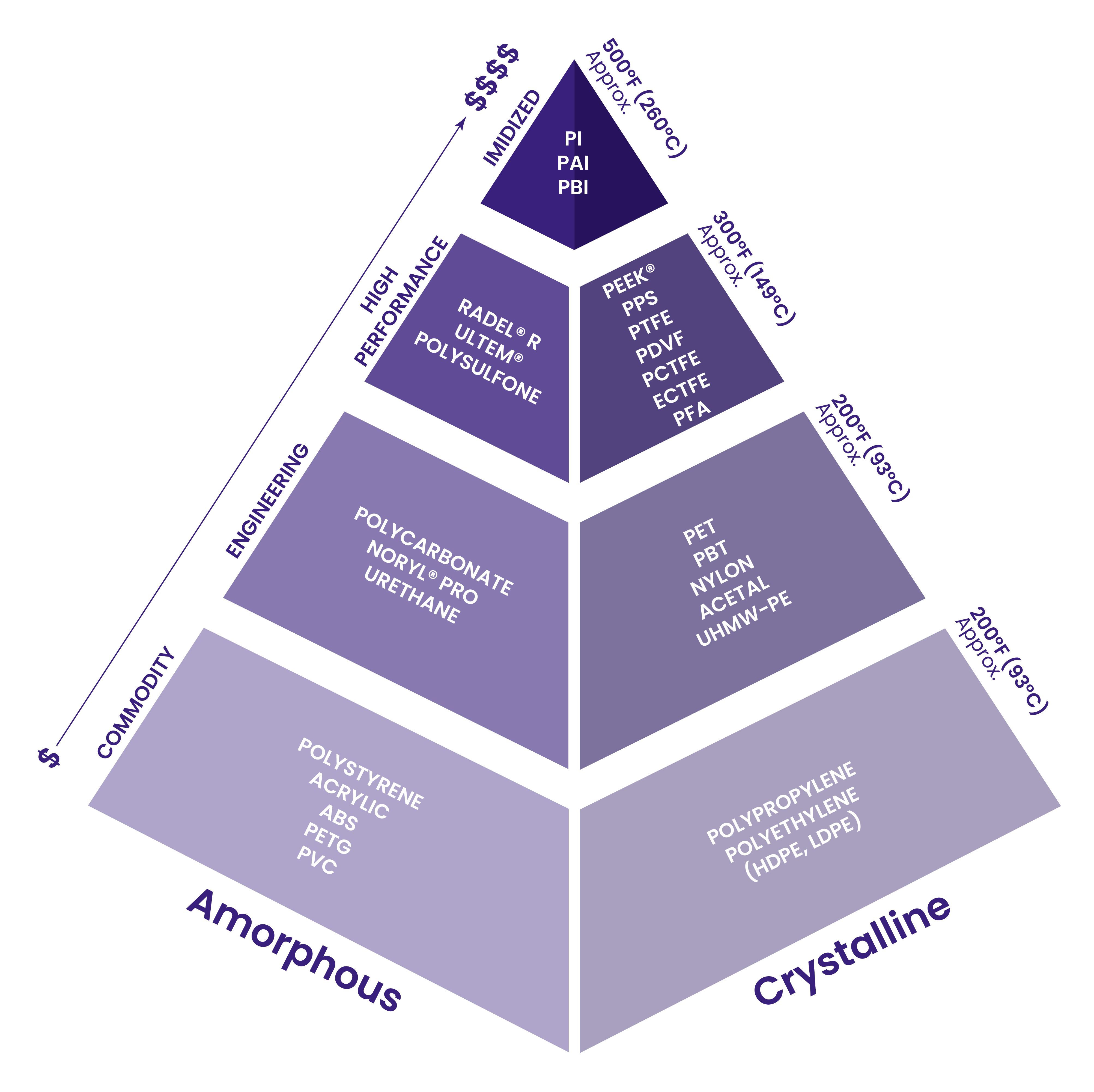

Choosing the right plastic is one of the most critical decisions in any injection molding project. This choice dictates a part's mechanical strength,...

Choosing the Right Material for Injection Molding: A Comprehensive Guide Material selection is a critical aspect of injection molding, influencing...