Why Injection Molding is Essential for Mass Production

Introduction In the realm of mass production, efficiency and cost-effectiveness are paramount. Industries worldwide strive for manufacturing...

3 min read

Nick Erickson : Feb 20, 2025 11:43:11 AM

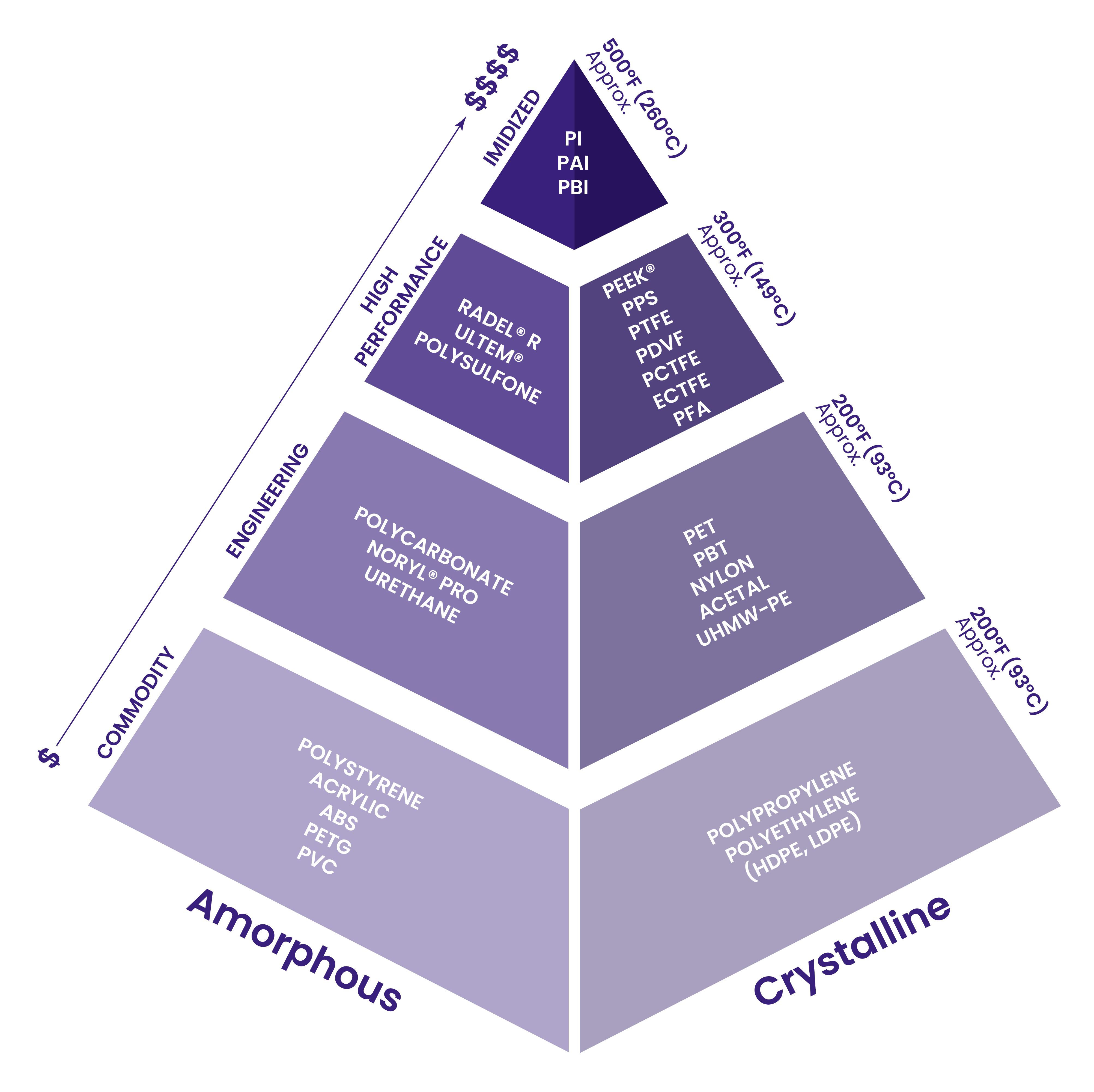

Material selection is a critical aspect of injection molding, influencing both the performance and cost of your final product. Whether the part ends up in a car, a medical device, or an aircraft, materials matter. Getting that mix of performance, durability, and manufacturability right makes all the difference.

As you compare your options, weigh heat resistance, chemical resistance, electrical properties, and dimensional stability against raw material cost and tooling constraints, then validate with prototypes under expected loads and temperatures to confirm performance across your part’s full service conditions.

The material selection pyramid (featured above) provides a clear framework for categorizing injection molding materials by performance, cost, and thermal resistance. Here's how to navigate this landscape.

You'll want to start by thinking about what the part actually has to do in order to decide what injection molding material you want to use.

Those needs point you toward the right tier of materials in the pyramid.

Think of the material pyramid as a quick way to sort through the various available plastics by performance and cost.

Commodity Materials (Base Layer):

This group covers the standard plastics you see everywhere: polystyrene, acrylic, and ABS. They’re inexpensive, mold easily, and do the job for low-stress parts, like packaging, toys, or basic consumer goods.

Engineering Materials (Middle Layer):

Polycarbonate, nylon, and acetals fall into this category — they handle more load, heat, and wear, which makes them a solid choice for things like automotive parts, tools, and industrial housings.

High-Performance Materials (Upper Layer):

PEEK, polysulfone, and PPS live here. They’re built for tough conditions — high heat, chemical exposure, nonstop use — that’s why they show up in aerospace, medical, and lab components.

Mid-sized High Performance (Peak of the Pyramid):

At the top are materials such as PI and PAI that are more expensive but worth it. These materials stay stable past 500°F (260°C) and are chosen when failure simply isn’t an option

Cost is a significant factor in material selection. The pyramid visually demonstrates that as you move up, the performance of materials increases, but so does the price. Choosing the right material involves striking a balance between the cost of production and the functional requirements of the product.

For example:

Material selection doesn’t stop at choosing a resin from the pyramid. Make the parts, then run them through the same conditions they’ll see in the field, and see where they hold or fail.

Comparing injection molding materials comes down to what the part has to do and where it’ll live. Some plastics are inexpensive and simple to mold but may start to break down under heat or heavy load. Others can take a beating, stay rigid, or resist chemicals, but they’ll cost more and might be trickier to mold. No one material fits every job—the right pick depends on the strength, flexibility, and wear the part needs to handle. Testing a few options early saves time, money, and frustration once production starts. At Aprios, we evaluate all these factors to match the right resin to your application and environment.

The material pyramid lays out how different plastics perform and what they cost. The only way to know you’ve picked right is to test parts in real use, see how they behave, and adjust as needed before scaling up. At Aprios, we work side by side with engineers to sort through material options, test samples, and fine-tune designs until everything runs the way it should.

Contact us today to discuss your project and take the first step toward creating high-quality injection-molded products.

Introduction In the realm of mass production, efficiency and cost-effectiveness are paramount. Industries worldwide strive for manufacturing...

What Is Discoloration? Discoloration in injection molding refers to any noticeable inconsistencies in the color of molded parts, such as streaks or...

What Are Voids? Voids are empty pockets or spaces that form inside your molded parts. While they might not always be visible from the outside, they...