Polyphenylsulfone (PPSU): High Performance for Tough Uses

Polyphenylsulfone (PPSU) is a high-performance amorphous thermoplastic belonging to the sulfone polymer family. Renowned for its exceptional...

5 min read

Nick Erickson : Nov 3, 2025 11:12:00 AM

Polyphenylene Ether (PPE), also sometimes known commercially as Polyphenylene Oxide (PPO), is a high-performance amorphous engineering thermoplastic known for its outstanding heat resistance, dimensional stability, and mechanical properties. However, due to inherent challenges in processing the pure resin stemming from its very high melt viscosity, PPE is rarely used on its own. Instead, it is almost always blended or alloyed with other polymers, most commonly polystyrene (PS), polyamide (PA), or polypropylene (PP), to create modified PPE (mPPE) grades. These blends improve processability and tailor performance to application-specific needs across industries like medical injection molding, fluid handling, and electrical systems.

Read More About Maximizing Mold Longevity with Aprios' Maintenance Strategy

Modified PPE blends inherit many of the base polymer's beneficial traits, resulting in materials with a compelling profile for engineering components.

Pure PPE possesses a high glass transition temperature around 410°F (210°C). While blending can adjust this threshold, many mPPE grades maintain heat resistance with HDTs ranging from 212°F (100°C) to over 392°F (200°C), supporting use in injection molding tooling and high-temperature environments.

PPE absorbs very little moisture and exhibits a low coefficient of thermal expansion. As a result, mPPE parts resist deformation from humidity or temperature changes—ideal for plastic injection mold design services and components requiring tight tolerances.

The chemical structure of PPE, lacking ester or amide groups susceptible to water attack, imparts superior resistance to hot water and steam. This makes mPPE an optimal material for medical device prototypes, fluid control systems, and repeated sterilization processes such as autoclaving.

PPE features low dielectric permittivity and a low dielectric loss tangent over a wide frequency range, characteristics largely retained in its blends. These properties are stable across varying temperatures and humidity levels, making mPPE a reliable choice for electrical housings, connectors, circuit breakers, and other insulating components.

Modified PPE resins offer good resistance to many chemicals, notably acids, bases, and salt solutions. However, pure PPE is susceptible to attack from certain organic solvents, particularly aromatic hydrocarbons and halogenated solvents. The resistance profile of an mPPE blend will depend significantly on the alloying polymer (e.g., PA blends offer enhanced chemical resistance compared to PS blends).

With a specific gravity of just 1.06 g/cm³, PPE is among the lightest engineering plastics. mPPE blends preserve this benefit, enabling plastic injection molding companies to support automotive and consumer designs with lighter, fuel-efficient, and portable components.

Aprios offers expert DFM development services and plastic injection mold design services to ensure your components meet performance and regulatory requirements.

The versatility achieved through blending allows PPE to serve a diverse array of markets, leveraging its balance of thermal, mechanical, and dimensional properties.

The combination of heat resistance, dimensional stability, good electrical insulation, and the potential for flame retardancy makes mPPE widely used for electrical components like connectors, sockets, fuse boxes, circuit breakers, and housings for computers, printers, and copiers. Halogen-free, flame-retardant grades align with safety and ISO-certified manufacturing standards.

In the automotive sector, mPPE finds use in both interior and exterior parts. Instrument panels, speaker grilles, and trim benefit from its dimensional stability and heat resistance. Under-the-hood components like fuse boxes, engine covers, and connectors leverage its thermal and chemical resistance. Due to their high heat performance, PPE/PA blends excel in on-line painting and automotive injection molding services. Low density also contributes to vehicle lightweighting efforts.

Excellent hydrolysis resistance and chemical stability against many water-based solutions make mPPE suitable for components in contact with water, such as pump housings, impellers, valves, water meter parts, and components for water softeners and filtration systems. Grades with relevant certifications (KTW, WRAS, NSF) are available for potable water contact.

Biocompatible grades of mPPE are utilized in the healthcare industry. Its ability to withstand sterilization methods like autoclaving (steam), ethylene oxide (EtO), and gamma radiation, combined with its dimensional stability and chemical resistance, makes it suitable for surgical instruments, IV connectors, medical equipment housings, and trays. The precision achievable through medical injection molding with mPPE is valuable for these critical devices.

Structural housings and internal components for small and large appliances, power tools, and vending machines benefit from the impact strength, heat resistance, and dimensional stability of mPPE blends.

Read More About Ensuring Consistent Quality with Tailored Quality Control Plans

As discussed, blending PPE with other polymers (PS, PA, PP, TPEs) is the primary modification strategy. Beyond alloying, various additives further tailor mPPE performance.

Glass fibers and, less commonly, carbon fibers or mineral fillers like mica are added to significantly increase stiffness, strength, and heat deflection temperature. Reinforced grades are used for structural components requiring high rigidity and load-bearing capability.

PPE has a relatively high oxygen index, making it inherently easier to render flame retardant. Various flame retardant packages, often halogen-free formulations (based on phosphorus or nitrogen compounds), are incorporated to meet specific flammability ratings (e.g., UL94 V-0) required in electrical and appliance uses.

To improve toughness, particularly at low temperatures, impact modifiers (often elastomeric materials) are incorporated into the blend. This enhances resistance to cracking under impact, important for automotive parts and durable goods.

Heat stabilizers can further enhance long-term thermal endurance, while UV stabilizers are added to mitigate color shift and property degradation upon exposure to ultraviolet light, although PPE/mPPE is generally not recommended for prolonged outdoor use without protection.

Like most thermoplastics, mPPE can be compounded with pigments and dyes to achieve a wide range of colors for aesthetic appeal or functional identification.

Despite its strengths, PPE and its blends have limitations to consider during material selection.

As mentioned, unmodified PPE has very high melt viscosity, making it difficult to process using conventional injection molding or extrusion techniques without very high temperatures that risk degradation. This is the primary reason for blending.

While resistant to many chemicals, PPE and particularly PPE/PS blends can be vulnerable to attack, softening, or cracking when exposed to certain organic chemicals, especially aromatic and chlorinated hydrocarbons, ketones, and some oils. Chemical compatibility must be carefully verified for the specific operating environment.

Some mPPE grades, particularly PPE/PS blends, can be susceptible to environmental stress cracking (ESC) when exposed to certain chemical agents under mechanical stress. Careful grade selection and design considerations are needed to mitigate this risk, especially in applications involving potential contact with aggressive chemicals or oils.

Without UV stabilization additives, mPPE can exhibit poor resistance to prolonged sunlight exposure, leading to color changes and degradation of mechanical properties. It's generally not favored for long-term outdoor applications unless specifically formulated or protected.

As an engineering thermoplastic, mPPE is generally more expensive than commodity plastics like polypropylene or ABS, and its cost is typically higher than some competing engineering resins like PC/ABS blends.

Leverage our rapid prototyping services, ISO 13485 injection molding, and precision manufacturing services for medical, automotive, and industrial applications.

Modified Polyphenylene Ether (mPPE) blends offer a compelling property profile for components demanding high dimensional accuracy, stability in moist or high-heat environments, and reliable electrical insulation. Its inherent resistance to hydrolysis makes it a strong candidate for fluid handling systems and devices requiring repeated steam sterilization, common in the medical field. The ability to tailor properties through blending and additives—achieving variations in heat resistance, flame retardancy, impact strength, and rigidity—provides significant design flexibility. Thanks to its low density and customizable properties, mPPE is also a great choice for lightweight yet durable applications that require custom manufacturing services, secondary operations, or design for manufacturing solutions.

Read More About The Ultimate Guide to ABS for High-Performance Manufacturing

Partner with Aprios—an ISO-certified manufacturing company offering expert injection molding services, DfM for medical devices, and tooling solutions. We’ll help you choose the right mPPE grade and streamline production with our rapid prototyping services and quick-turn injection molding capabilities.

Explore our Material Selection Tool or contact us to get started with your next high-performance project!

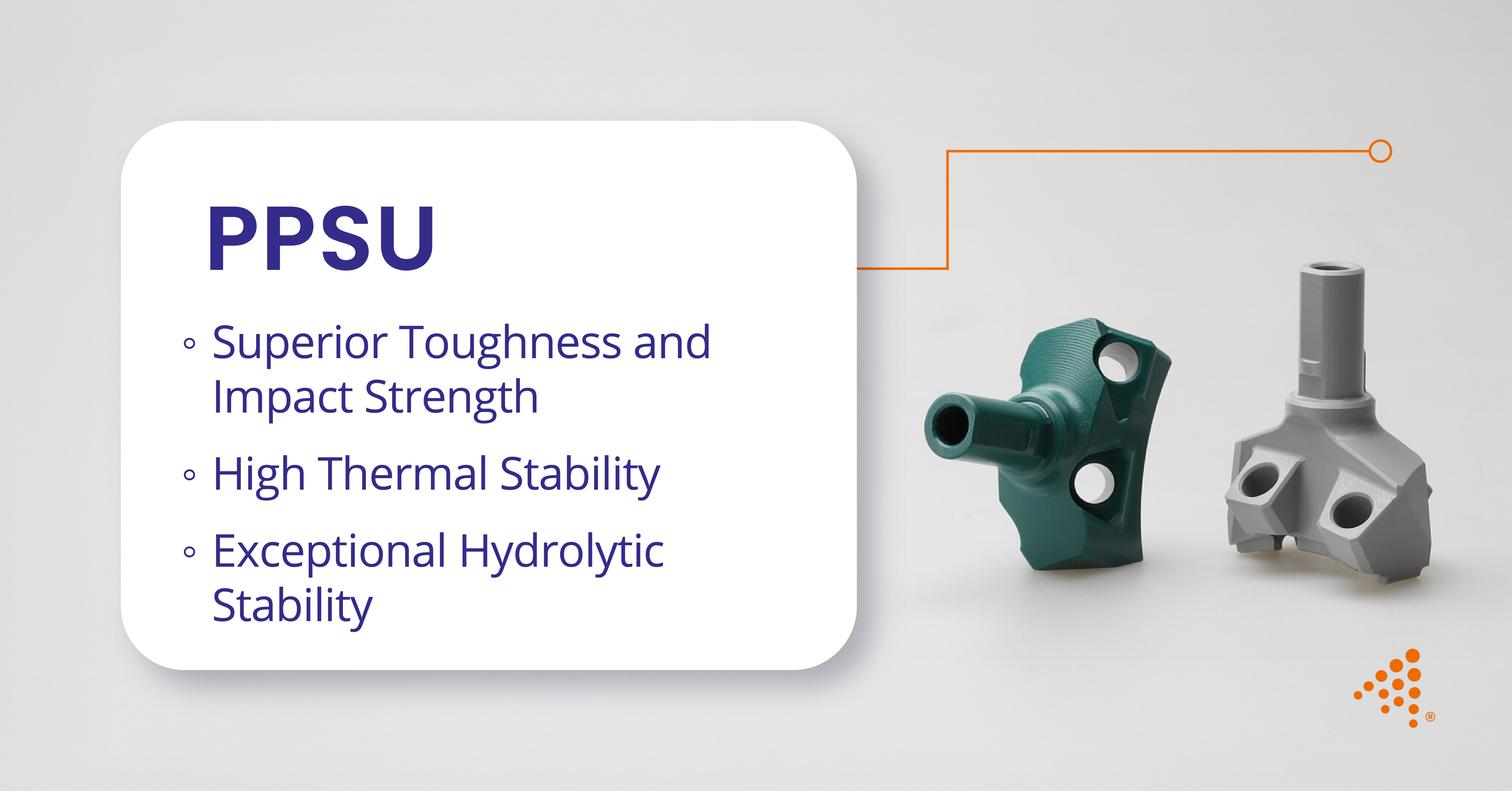

Polyphenylsulfone (PPSU) is a high-performance amorphous thermoplastic belonging to the sulfone polymer family. Renowned for its exceptional...

Polyetheretherketone (PEEK) is a high-performance, semi-crystalline thermoplastic renowned for its exceptional combination of mechanical strength,...

Polybutylene Terephthalate (PBT) is a high-performance thermoplastic resin known for its chemical resistance, moderate heat tolerance, and strong...