POM (Acetal/Delrin): Resin for Precision Components

Polyoxymethylene (POM), commonly known as acetal or polyacetal, is a high-performance engineering thermoplastic celebrated for its impressive...

5 min read

Nick Erickson : Jul 14, 2025 8:33:00 AM

Polyphenylene Sulfide (PPS) is a high-performance, semi-crystalline engineering thermoplastic known for its remarkable thermal stability, chemical resistance, and mechanical strength—even at elevated temperatures. It stands out as a reliable choice for components exposed to aggressive conditions, making it a material of choice across various sectors including automotive, electronics, aerospace, and medical injection molding.

Read More About Guide to Polypropylene (PP): A Versatile Material for Manufacturing

PPS is engineered to meet stringent requirements in hostile environments. Its thermal resilience, chemical inertness, and processability through injection molding services make it ideal for manufacturing precise, high-strength components.

One of the most defining traits of PPS is its ability to maintain structural integrity and mechanical properties at high temperatures. It boasts a continuous use temperature of up to around 428°F (220°C) and can withstand short-term exposure to even higher temperatures, making it ideal for under-the-hood automotive parts, electrical components, and sterilizable medical device prototypes.

PPS exhibits outstanding resistance to a wide array of chemicals, including fuels, oils, solvents, acids, and bases, even at elevated temperatures where many other plastics would fail. Below approximately 392°F (200°C), PPS is practically insoluble in any known solvent. This inertness is crucial for parts used in aggressive chemical environments, such as those found in filtration systems, chemical processing equipment, and certain medical injection molding processes involving chemical exposure.

Even without reinforcement, PPS offers good tensile strength and rigidity. When reinforced, typically with glass fibers or minerals, its strength, stiffness, and creep resistance increase significantly, allowing it to function effectively under mechanical loads over long periods and at high temperatures. This makes reinforced PPS a viable alternative to metal in some structural components.

PPS possesses inherent flame retardant properties, typically achieving a UL94 V-0 rating without the need for flame retardant additives. This means it self-extinguishes quickly upon removal of a flame source and produces minimal smoke, a critical safety feature for electrical enclosures, connectors, and aerospace components.

PPS maintains its shape and dimensions exceptionally well across a wide range of temperatures and humidity levels. Its low coefficient of thermal expansion and low moisture absorption contribute to tight tolerance capabilities and predictable performance in precision parts, which is vital for intricate assemblies found in electronics and medical devices.

This material provides reliable electrical insulation properties that remain stable across variations in temperature and frequency. Its dielectric strength and arc resistance make it suitable for insulating applications in high-voltage environments, such as connectors, sockets, coil forms, and switch components.

Explore Aprios' custom injection molding solutions and injection molding tooling options tailored for PPS and other high-performance materials.

The robust characteristics of PPS lend themselves to a diverse range of uses where performance under stress is paramount. From automotive systems to complex medical tools, PPS provides reliability where other materials might falter.

Due to its high heat resistance, chemical inertness, and mechanical strength, PPS is frequently used in demanding automotive systems. Common uses include fuel system components, pump housings, impellers, coolant system parts, sensors, lamp sockets, and powertrain components that experience high temperatures and exposure to automotive fluids.

Its inherent flame retardancy, dimensional stability, and good electrical insulating properties make PPS a prime choice for electrical and electronic components. Examples include connectors, sockets, switches, relays, coil bobbins, motor brush holders, and housings for integrated circuits and other sensitive electronics that require stability during soldering processes.

In the industrial sector, PPS is used for pump housings, valves, impellers, seals, and filter components that must handle corrosive chemicals or operate at high temperatures. Its durability and chemical resistance ensure longevity in harsh processing environments, like those in the oil and gas or chemical manufacturing industries.

The ability of PPS to withstand repeated sterilization cycles (steam, gamma, EtO) without significant degradation, combined with its chemical resistance and biocompatibility (in specific grades), makes it suitable for certain medical instruments, surgical tool handles, and diagnostic equipment components. Its use in medical injection molding allows for the production of precise, sterilizable parts.

Lightweight yet strong and flame retardant, PPS finds uses in aerospace for interior components, electrical system parts, and other areas where high performance and safety standards are required. Its resistance to aviation fluids is also a key advantage.

In high-end appliances, PPS might be used for components requiring heat resistance, such as parts in microwaves, ovens, or hair dryers. Its durability and resistance to heat and chemicals ensure reliable performance in these consumer-facing items.

Read More About Injection Molding Defects: Discoloration – Why It Happens and How to Avoid It

Enhancing PPS through additives can tailor its properties for specific applications, especially in design and manufacturing services.

Adding glass fibers (typically 10-40% by weight, or sometimes higher) is the most common modification for PPS. This significantly increases tensile strength, stiffness, creep resistance, and heat deflection temperature, making it suitable for load-bearing structural components that require enhanced mechanical performance.

Minerals like calcium carbonate, talc, or wollastonite can be added to improve dimensional stability, reduce warpage (especially in complex injection molding designs), increase stiffness, and lower the coefficient of thermal expansion. Mineral-filled grades often offer a balance between cost and performance enhancement.

For applications requiring even higher stiffness, strength, and potentially electrical conductivity or enhanced thermal conductivity compared to glass fiber reinforcement, carbon fibers can be used. Carbon-fiber-filled PPS is often specified for high-performance structural parts in aerospace or industrial machinery.

Internal lubricants such as Polytetrafluoroethylene (PTFE), graphite, or silicone oils are incorporated to reduce the coefficient of friction and improve wear resistance. These self-lubricating grades are ideal for bearings, bushings, gears, and sliding components where low friction and durability are critical.

Although inherently somewhat brittle, especially in unfilled grades, the toughness and impact resistance of PPS can be improved by adding specific impact modifiers. This is beneficial for components that might experience sudden shocks or stresses during operation.

While naturally an off-white or tan color, PPS can be compounded with various pigments and dyes to achieve specific colors required for branding, identification (e.g., in electrical connectors), or aesthetic purposes. High-temperature stable colorants are necessary due to the high processing temperatures of PPS.

Aprios delivers precision manufacturing services and DfM support optimized for PPS and other advanced thermoplastics.

Despite its many strengths, PPS does have certain limitations that engineers and designers must consider during material selection.

Standard, unfilled PPS grades can be relatively brittle compared to some other engineering thermoplastics, particularly at room temperature or lower. While reinforcement improves toughness, care must be taken in designs involving sharp corners or potential impact points, especially if using unfilled material.

PPS requires high melt processing temperatures, typically in the range of 570-645°F (300-340°C), and high mold temperatures (often above 266°F (130°C)). This necessitates processing equipment capable of handling these temperatures and requires careful control during the injection molding process to achieve optimal properties and avoid degradation.

As a high-performance engineering thermoplastic, PPS generally carries a higher price tag compared to commodity plastics or even some other engineering plastics like polyamides or polycarbonates. Its use is typically justified by demanding performance requirements that commodity materials cannot meet.

PPS is naturally opaque (typically tan or off-white). It cannot be made transparent, limiting its use in applications where optical clarity is required, such as sight glasses or clear housings.

Read More About Injection Molding Voids: Causes & Solutions

Choosing PPS is often driven by the need for a material that can reliably perform under conditions that would cause other plastics to fail, particularly regarding heat and chemical exposure. Its combination of thermal stability, broad chemical resistance, inherent flame retardancy, and excellent dimensional stability makes it indispensable for critical components in automotive, electrical, industrial, and demanding medical applications. When reinforced, its mechanical properties approach those of some metals, offering opportunities for weight reduction without sacrificing performance. For designs requiring precision, durability, and resilience in harsh environments, PPS provides a robust and dependable solution, particularly valuable in high-precision injection molding for complex parts.

At Aprios, we can help you choose the right PPS material for your specific needs. Get in touch for expert advice and solutions tailored to your project!

You can also view our Material Selection tool.

Polyoxymethylene (POM), commonly known as acetal or polyacetal, is a high-performance engineering thermoplastic celebrated for its impressive...

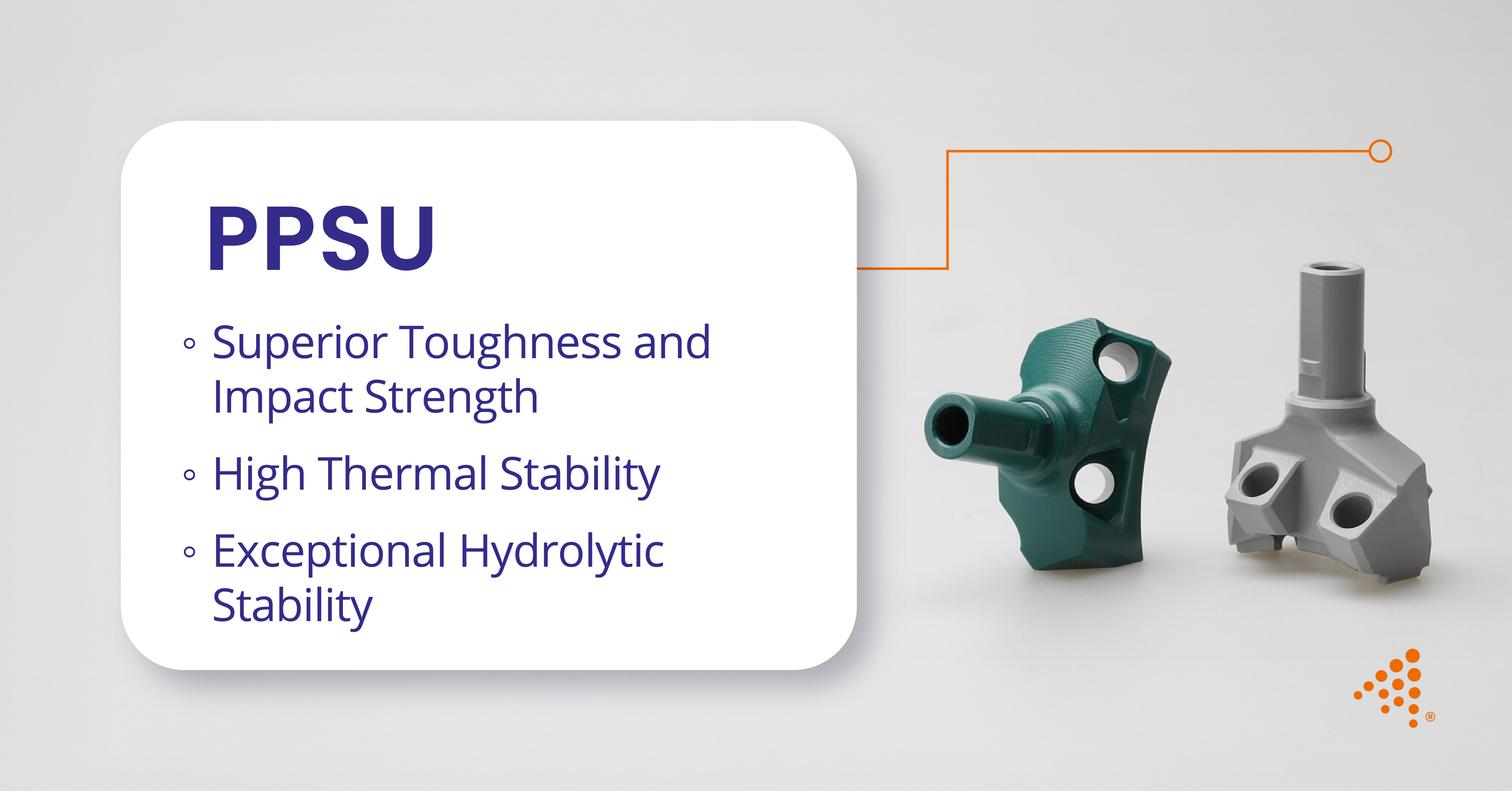

Polyphenylsulfone (PPSU) is a high-performance amorphous thermoplastic belonging to the sulfone polymer family. Renowned for its exceptional...

Polyetheretherketone (PEEK) is a high-performance, semi-crystalline thermoplastic renowned for its exceptional combination of mechanical strength,...