Choosing the Best Surface Finish for Injection Molded Parts

When developing a plastic part through injection molding, the surface finish might initially seem like a purely aesthetic choice. However, its...

4 min read

Nick Erickson : Dec 13, 2025 9:30:00 AM

The moment a new plastic part solidifies within the steel confines of an injection mold is a defining one. In an ideal cycle, the mold opens, and the part is ejected cleanly, ready for the next stage. However, unseen forces are at play. As the plastic cools, it shrinks and grips the mold's core, creating significant friction. Overcoming this friction is paramount to a successful molding process, and the solution lies in a simple but foundational design element: the draft angle.

Understanding and correctly applying a draft angle is a fundamental aspect of Design for Injection Molding (DfIM) and Design for Manufacturing (DFM) that affects part quality, cycle time, and tooling longevity. While it may seem like a minor adjustment, this slight taper is the key to preventing a host of problems, from cosmetic flaws to critical part damage. This article will explore what a draft angle is, why it is so important, and how to determine the appropriate amount for your project.

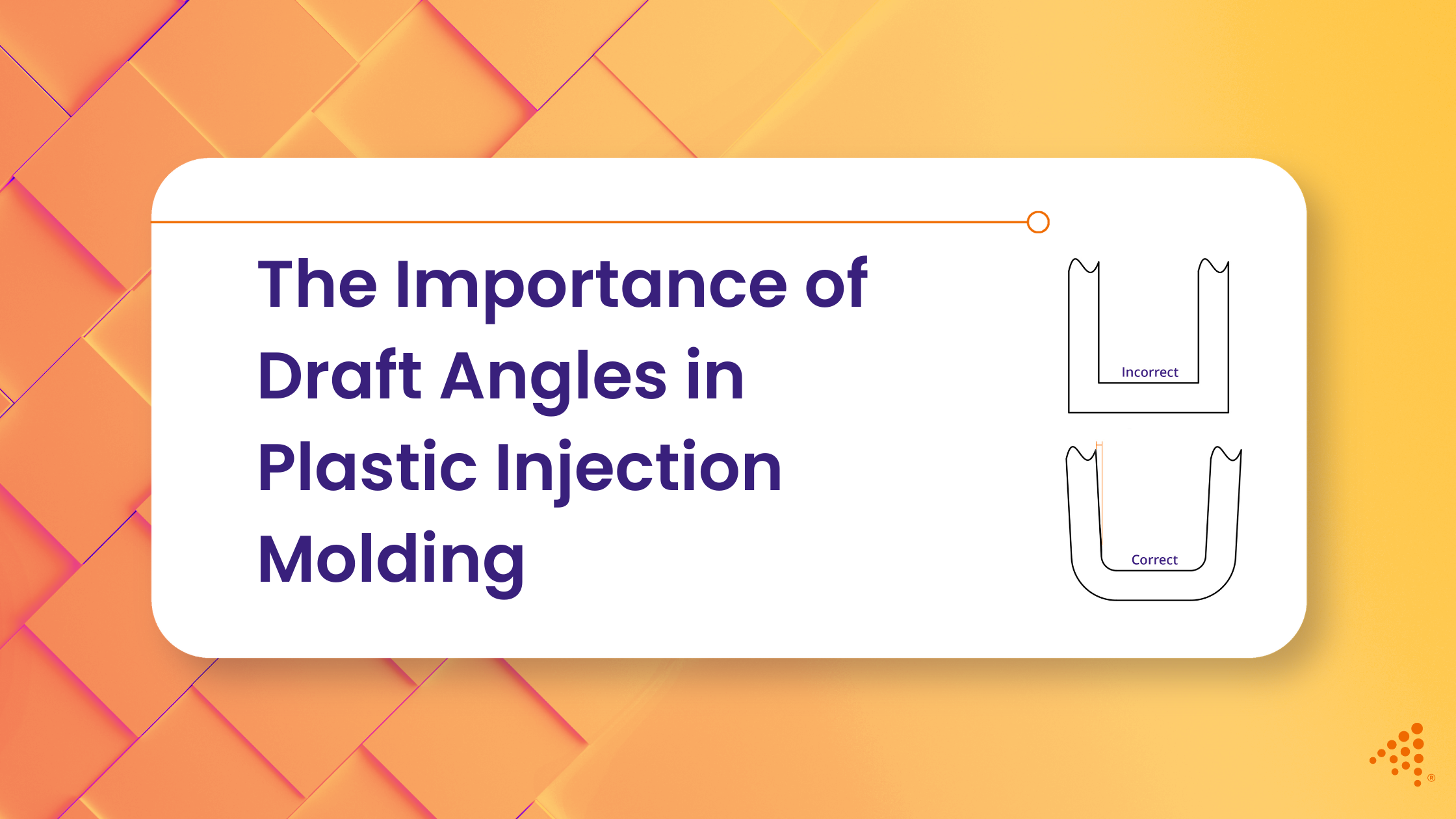

A draft angle is a small degree of taper applied to the vertical walls of a part in the direction of the mold's pull. Imagine trying to pull a perfectly straight-sided cylinder out of a tight-fitting container; the friction along the entire surface makes it difficult. Now, imagine the cylinder is slightly tapered, like a disposable cup. It releases with minimal effort. This is the principle of a draft angle in action. It allows the part to separate from the mold surface as soon as the ejection process begins, minimizing friction and preventing damage.

Without this taper, the part surface would drag along the mold wall during ejection. This can cause vertical scratches known as "drag marks," scuff the part's surface, or, in severe cases, cause the part to deform or break. The force required to eject a part with zero draft can also put immense stress on the ejection system and the mold itself, leading to premature wear and tear on expensive plastic injection mould tooling.

Read More Boost Efficiency with Functional Integration in Additive Manufacturing

For industries like Medical Injection Molding, cosmetic perfection is often a quality requirement. A drag mark that might be acceptable on a consumer product could lead to the rejection of a medical component or even delay Medical Device Prototypes. An insufficient draft angle is often the culprit behind these surface defects.

Beyond aesthetics, a lack of proper draft can lead to several manufacturing issues:

This is why injection mold design services, DFM services, and design for manufacturing solutions are critical during early-stage planning. They help ensure the draft is properly integrated before costly tooling is built.

The finish of the mold wall has the most significant impact on the required draft. A highly polished, smooth surface (like an SPI-A1 finish) releases much more easily and can often function with as little as 0.5 degrees of draft on shallow features.

Conversely, a textured surface creates thousands of microscopic undercuts that the plastic flows into. Ejecting a textured part without adequate draft will scrape and damage both the part and the mold. A widely accepted guideline is to add 1 to 1.5 degrees of draft for every 0.001 inches (0.025 mm) of texture depth.

The properties of the chosen plastic resin also play a role. As a material cools, it shrinks. Materials with higher shrink rates will contract more tightly onto the mold core, generally requiring a greater draft angle to facilitate release. Softer, more flexible materials like TPEs might be more forgiving, while rigid, brittle materials may need more assistance from a generous draft angle to prevent cracking during ejection.

The depth of a wall or feature is another important consideration. A tall, deep rib has significantly more surface area in contact with the mold than a short one. This increased surface area results in more friction to overcome. For deeper parts, it is a good practice to add more drafts. A common guideline is to add a degree of draft for every inch of depth. A part with a 3-inch deep cavity would benefit from at least 3 degrees of draft, even with a smooth finish.

Different features on a part require individual consideration. Internal surfaces, such as the inside of a box or a cored-out boss, shrink onto the mold core and therefore need more draft than external surfaces that shrink away from the mold cavity. Features like ribs, gussets, and louvers should all incorporate a draft to prevent damage during ejection.

Struggling with Part Ejection Issues?

Our injection molding manufacturers deliver optimized designs with proper draft angles to prevent warpage and defects.

While every part is unique, these guidelines provide a solid foundation for initial design:

Ultimately, the optimal draft angle is a key point of discussion during a comprehensive DFM analysis with your manufacturing partner. Finalizing these details before tool production begins is essential for achieving a smooth, efficient, and cost-effective manufacturing process.

At Aprios, our DFM development services include a thorough analysis of every feature to determine the optimal draft angle for clean ejection and superior part quality. We offer Rapid Prototyping Services, 3D Printed Prototypes, additive manufacturing services, and precise tooling solutions to ensure designs are production-ready.

From Prototype Injection Molding and Quick Turn Injection Molding to full-scale Custom Injection Molding Solutions, we are a trusted design and manufacturing company and injection molding company delivering excellence in design for manufacturing services and custom manufacturing services.

Our ISO-Certified Manufacturing Company combines inspection and quality control in manufacturing with strategic supply chain solutions to ensure reliable, repeatable production.

When developing a plastic part through injection molding, the surface finish might initially seem like a purely aesthetic choice. However, its...

Bringing a new product to market is a complex balancing act. Innovation must be weighed against the pressures of time-to-market and, most...

Dimensional accuracy is essential in the field of precision injection molding. However, even when a part is molded to exact specifications, it can...